Understanding the Roots of Papermaking

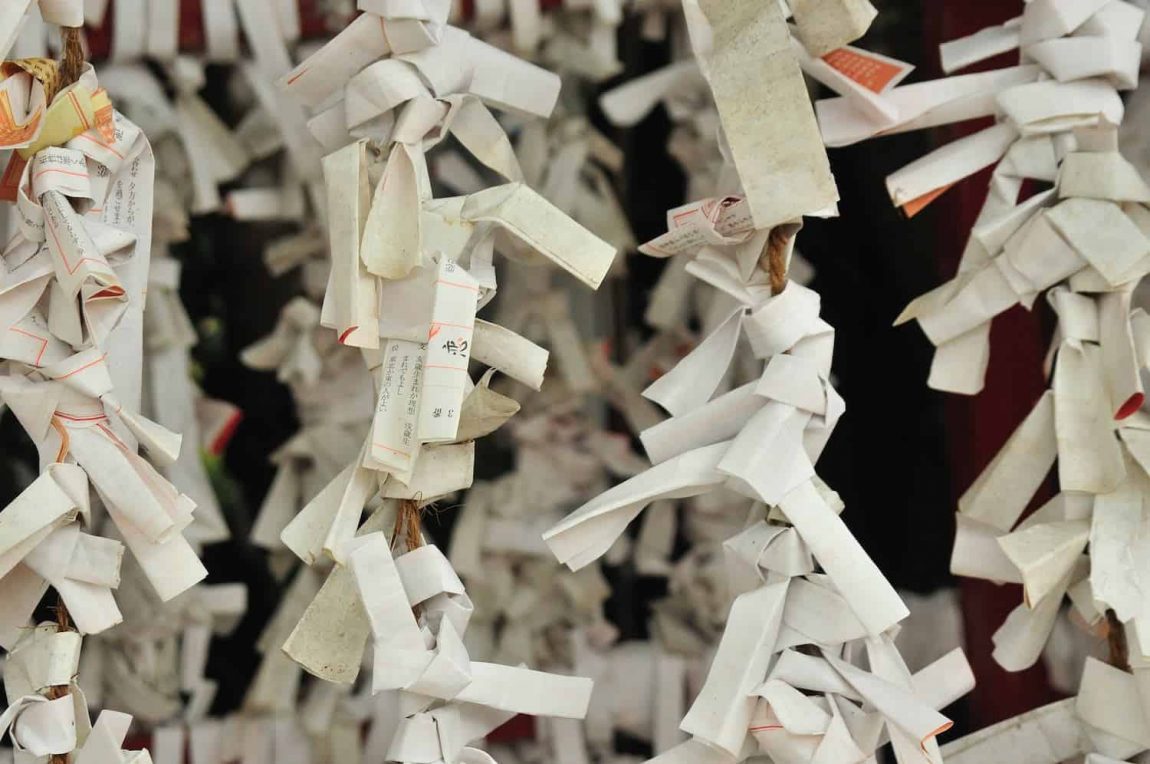

The Dawn of Papermaking: A Historical Perspective

The journey of papermaking began in ancient China during the 2nd century, marking a significant shift from silk to a more accessible writing material. This innovation quickly spread, reaching Europe by the 12th century. The evolution of papermaking over the centuries has been a cornerstone in the development of global information networks.

Innovations and Advancements in Paper Production

By the end of the 18th century, papermaking had undergone a revolutionary change with the invention of the first paper machine by Louis Robert in France. This invention paved the way for the mechanized production of paper, leading to a wide variety of paper types that cater to different uses, including writing, printing, and packaging.

The Science of Papermaking: An In-Depth Look at the Process

The Starting Point: Pulp Production

The first critical step in paper manufacturing is the production of pulp from wood chips. Softwoods like spruce and pine, known for their slender, strong, and elastic fibers, are commonly used in North America. The pulp, essentially the raw material of paper, can be produced through two primary methods: chemical pulping and mechanical pulping.

Chemical Pulping: Achieving Superior Quality

Chemical pulping involves breaking down the chemical structure of lignin into a liquid using various chemicals, including sodium hydroxide and sodium sulfide. This process results in a higher-quality paper, albeit at a more expensive production cost compared to mechanical pulping.

Mechanical Pulping: An Efficient Alternative

Mechanical pulping, divided into ground pulping and thermo-mechanical pulp (TMP), keeps lignin intact within the fibers, unlike chemical pulping. This method is known for its higher yield and is typically used for producing paper with lower strength properties.

The Fourdrinier Machine: Revolutionizing Paper Formation

The widespread use of the Fourdrinier machine has been instrumental in the production of diverse paper types. This machine facilitates the formation of a fiber mat, crucial for the creation of various papers, including newspapers, wrapping papers, and specialty papers.

Key Steps in the Fourdrinier Process

- Treatment of raw materials: Converting chips into pulp, washing, bleaching, refining, and coloring.

- Forming the paper sheet: Draining water from the pulp and forming a thin sheet of fiber mat.

Bleaching: Striving for Whiteness and Strength

For papers like writing papers, whiteness is a critical attribute. Oxygen bleaching techniques are predominantly used for pulp bleaching, considering their lower environmental impact compared to chlorine bleaching. This process removes dark color lignin and enhances the paper’s strength through hydrogen bonds between fibers.

Refining and Calendering: Enhancing Quality

The refining process, often involving a conical refiner, improves the pulp quality before it is fed into the Fourdrinier machine. Calendering then enhances the physical and mechanical properties of the paper, contributing to its final texture and finish.

The Final Touches: Coating and Finishing

Depending on the paper type, additional finishing processes may be employed. Coatings are applied to the paper surface to achieve desired effects, such as matte, semi-matte, or glossy finishes.

The Properties of Paper: A Closer Look

Mechanical and Physical Properties

The quality of paper is determined by several factors, including tensile strength, compression strength, bending stiffness, tear resistance, and burst resistance. Techniques like the Sheffield smoothness tester and the stylus profilometer are employed to measure surface smoothness, a key factor in printability.

The Future of Papermaking: Sustainability and Innovation

As the paper industry evolves, sustainability and eco-friendly practices are becoming increasingly important. Innovations in recycling, use of alternative raw materials, and advancements in production techniques are shaping the future of papermaking, ensuring its relevance and sustainability for generations to come.