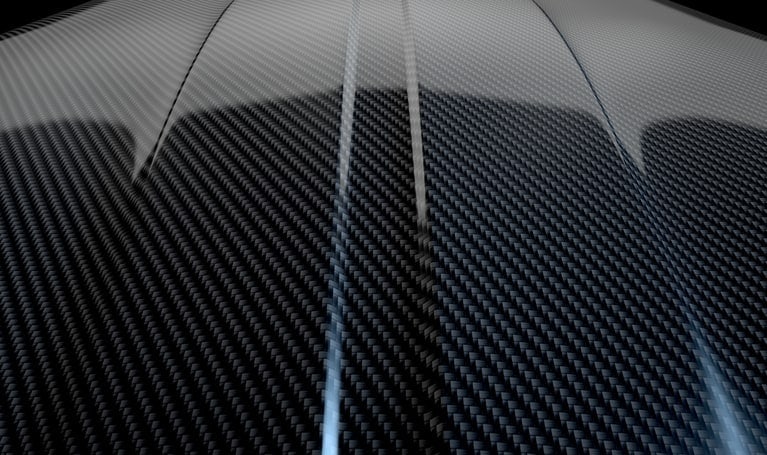

Composite materials making use of carbon fiber are becoming more prevalent in the industries of automation and robotics. The lighter airframe affords weight-saving methods and heightened productivity. Found in several engineering and design elements, carbon fiber offers longer longevity, enhances the overall design, and simplifies the molding and application process. Several materials traditionally used by manufacturers are being replaced by carbon fiber, given the diverse benefits that it offers. Producers

Some producers have difficulty offering the appropriate amount of product necessary in such large amounts with the current inspection and automation processes. Manual inspection processes can be lengthy and riddled with errors. Replacing and improving these processes can mitigate operational costs, errors and enhance the overall efficiency in these industries.

Benefits of Carbon Fiber

Some of the best advantages of using carbon fiber are used in the automotive industry and make way for progress to be made while simultaneously increasing productivity and lowering costs. Carbon fiber has to be altered with great care in order to maintain its integrity. The design of carbon fiber allows for better accuracy in the manufacturing process, oftentimes improving robotic functionality by offering flexibility as well as stability and support.

- Up-to-date automated fiber placement layup process

- Lightweight and additional stability

- Diverse options (flat sheets, angles, rectangular tubes)

- Greater strength and substantial weight savings

- Lighter airframes

- Enhanced fuel efficiency

- Lower emissions

- Scalable for different volumes

- Simultaneously offers flexibility as well as stability

Carbon fiber is weight-bearing and can quickly be modified to be included in assembly lines and lower cost and time. The countless advantages of carbon fiber have resulted in applications in aerodynamics, as well as the automation and robotics industry. Carbon fiber is 75% lighter than sheet metal, granting it a substantial strength advantage over materials traditionally used in these industries. Consider, however, that carbon fiber costs 85% more to produce than regular traditional sheet metal. While this can be seen as a disadvantage, carbon fiber can also decrease operational costs while increasing productivity. In addition, quality assurance and direct process upgrades can also be incorporated into production, helping save time and money.

Carbon fiber can also be tailored to endure higher temperatures for extended longevity making it durable and valuable. Inspections that are efficient and effective are vital and necessary to aid from the use of these materials. On average, weight reduction is between 50% and 75% if used as an alternative to the several metal components that are becoming obsolete as a result. Carbon fiber can also be altered to provide the flexibility necessary to adapt to a specific need for a product. This can also allow for enhancement in flexibility and lower production time.

Research of the chemistry behind carbon fiber is currently being conducted to with the hopes of establishing this product as a cheaper and more accessible alternative to traditional materials.

Research is also being done to improve the material’s robust composition and compatibility with different machinery. It is also the subject of testing in robotics research to accommodate for robotic handling of such materials. With the goal of optimizing this material, new research is continually being done for solutions to productivity in the manufacturing industry.

The fields of automation and robotics can greatly benefit from using carbon fiber, specifically in regards to accuracy and productivity. As a consistently reliable material, carbon fiber’s record of improving productivity by reducing production time is proven. As a result, new jobs will be created and will aid in efforts to mass-produce diverse products. Resulting from recent advancements in automation, carbon fiber will pave the way for opportunities for positive advancements.