Steel is an increasingly popular material in the world of construction, both in residential and commercial buildings. With urbanization and the need for rapid construction to keep up with demand, steel’s affordability, strength, and durability have made it the go-to material for construction teams building frames. Most steels have to undergo different processes such as annealing, tempering, and precipitation hardening to ensure the steel’s strength, durability, ductility, etc.

Of course, as with any material, there are both pros and cons that need to be weighed up before its use. Here are some of the top considerations that construction and design teams need to think about:

Design Freedom

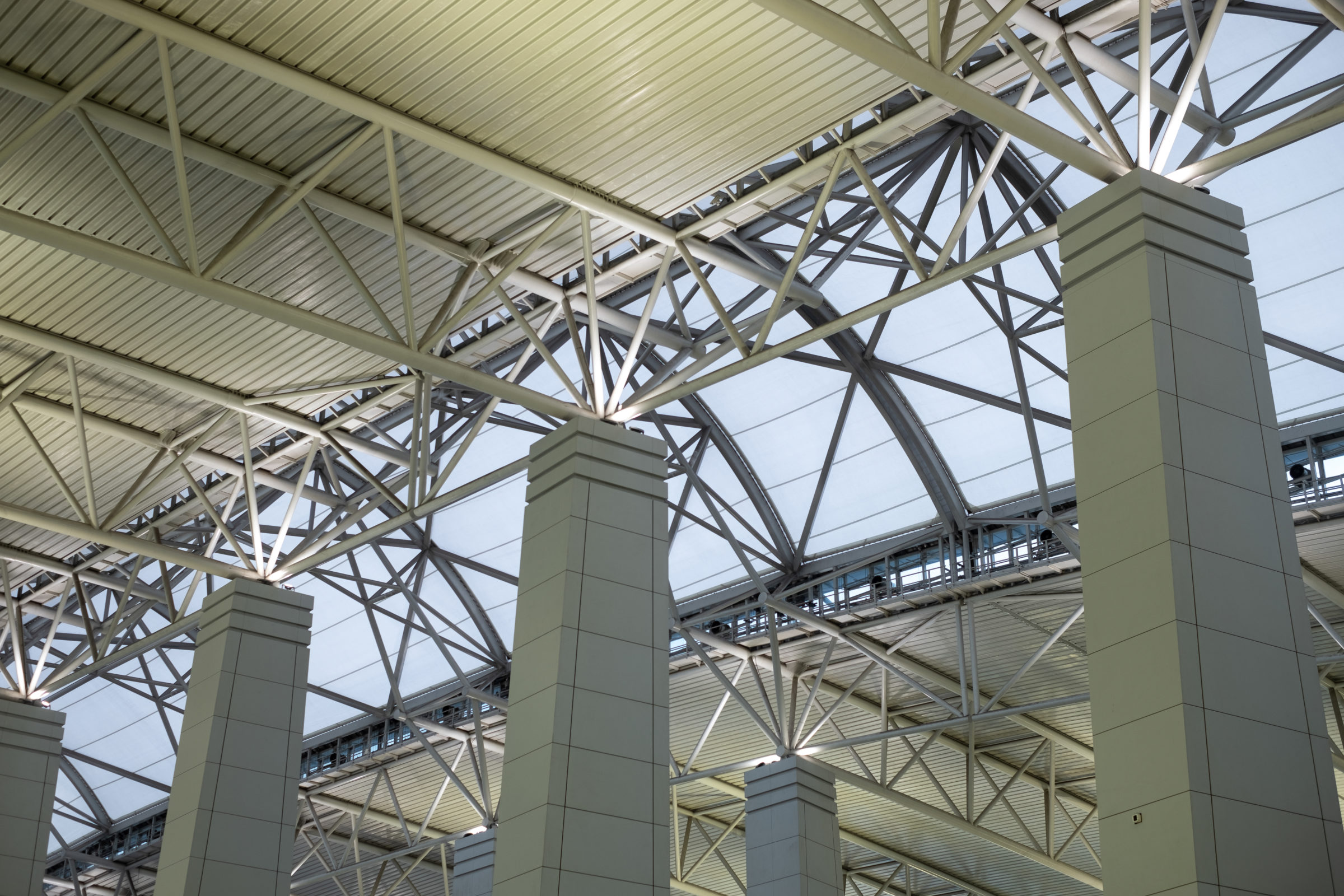

One of the biggest benefits that steel construction offers architects is design freedom. It is strong and durable which makes it possible to bend to create curves in a building’s form.

Steel is an excellent choice for arches and domes and is also visually quite appealing. There is more choice in colors and textures compared to other building frame materials.

Less Support Columns Needed

Steel frames give many more options for interior layouts in comparison to traditional frames. Less beams are required for support, meaning more open spaces can be created and if an interior change is desired then moving support to another location is relatively easy.

Speed and Efficiency

Steel frames are often manufactured in an off-site location and then delivered and quickly erected on the plot of land, this helps to minimize disruption to those in the local area, reduce labor costs and speed the process up significantly.

This in turn helps to keep the project in budget and to the projected timescale, meaning that overall the return on investment will be much quicker.

Recyclability

One of the major concerns currently impacting the construction sector is environmental sustainability and the damage that wasted material is causing to the planet and Earth’s natural resources. However, steel saves the use of natural resources by around 30 percent and can be re-used when a building is demolished.

There are many other uses for steel and it can be melted down and redesigned into something else.

Fire and Earthquake Resistance

Steel is also a great option from a safety perspective. Steel frame’s advanced design and specifications mean that less fire protection is required. Also, due to its flexibility, it is often able to flex during earthquakes, preventing the building from crushing or crumbling.

This equals better safety for those inhabiting the building and makes steel frame a popular choice for buildings located in areas at high risk of earthquakes and other natural disasters.

But… Steel frames are less energy efficient

While there are many reasons that steel is the ideal choice for a building frame, it is also important to consider the running costs that might come with this type of structure. One concern is energy efficiency and loss of heat.

Steel is more conductive than wood and therefore heat may move quickly through the walls. As a result, inhabitants might find that their energy bills are higher, and given the current cost of energy, this is a big concern for many businesses and homeowners.

However, there are ways that you can counteract this heat loss and make the building more efficient. For example, insulation boards can be wrapped around the beams, and cavity wall insulation can be added.

These are relatively low-cost options that will have a big impact on the energy efficiency of a steel frame building in the long run.

On balance, it is easy to see why steel is becoming such a popular building material for frame construction and as the need for affordable and durable properties continues to rise we can expect to see more of these in building types popping up.