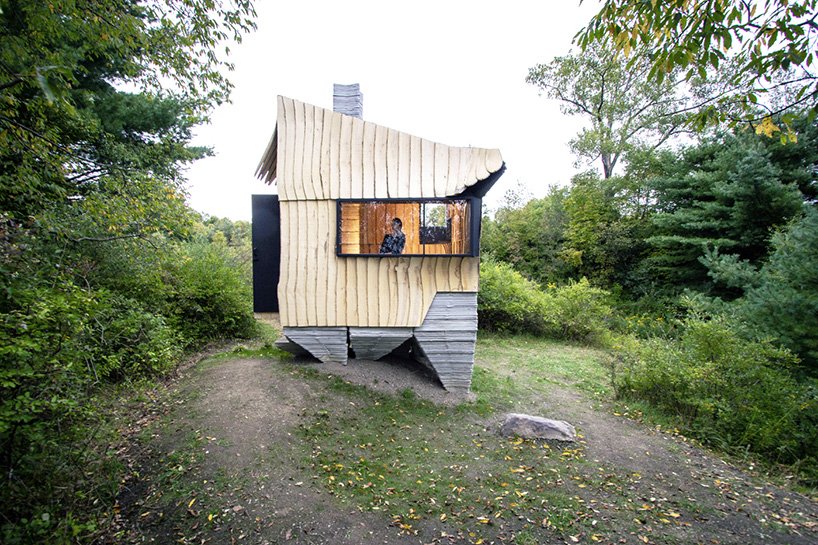

In Ithaca, New York Leslie Lok and Sasa Zivkovic started an innovative design and analysis studio called HANNAH. It’s working on a variety of scales – from urbanism to furniture. Digital layout and invention technologies are inherent in their work. Their newest project – HANNAH – which is wood that was supposed to go to waste but turned into a 3D-printed structure, and they named it an ashen cabin. It shows how new methods could help reuse what we would throw to waste.

Authors of this futuristic idea say that they want to dig the stress in between architectural ends and mechanical means—the 3D-printed cabin, located in the woods of Ithaca, NY. Exquisite detail is the wood that got used – the emerald ash-borer-infested wood. It turns this particular wood into material that is affordable, readily available, and sustainable. They achieved it thanks to robotic based invention technologies and precision 3D-scanning. Sasa Zivkovic comments that ash trees tend to decompose or burn, both ways release CO2 into the atmosphere. So the significant advantage of using compromised ash for creating a building is that it offsets the harvesting of more common wood kinds and attaches carbon to the planet. There were two phases of creating the cabin – setting the base floor, interior, and chimney constructed out of nine interlocking 3D-printed segments of concrete and the second made by six-axis robot found on the internet (eBay) that carved the wood for the facade. The arm of a robot helped with cutting wooden logs.

Leslie Lok confirms that concrete is guilty of 8% of total CO2 emissions. Using 3D printing, they eradicate the use of wasteful form and can smartly use concrete. HANNAH considerably reduces the use of concrete while keeping the integrity of the structure.

Website: www.hannah-office.org/